Genlux Lighting has acquired its own specialised light testing equipment and has set up a laboratory at its Triangle, Germiston, office premises to test its lighting products and designs.

“We are now able to conduct a much greater variety of tests than we were able to do previously, when we were wholly reliant on external certified third-party labs for testing purposes. We are also able to conduct tests much more frequently than before,” said Ian Marais, Genlux’s Systems Engineer who heads up the business unit’s team of product developers and lighting designers.

“Having our own in-house test facility enables us to do batch testing to more accurately establish the integrity of our products in accordance with their official certification requirements. We can now do more detailed and customised testing than before. In addition, it gives us much more scope than previously to develop and test workable new lighting designs,” he pointed out.

“This facility gives us the important advantage of enabling us to meet our customers’ requirements more efficiently, accurately and rapidly.”

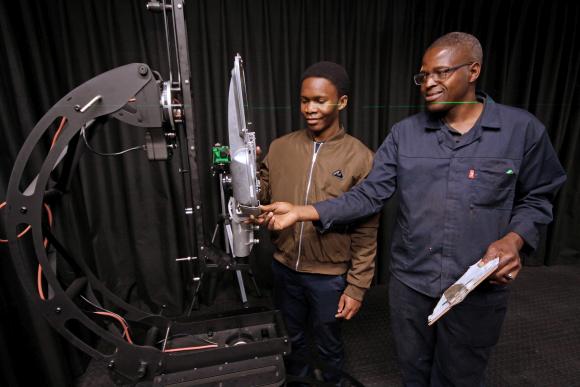

The lab has been operational since the beginning of August this year. The cutting-edge high-tech test equipment Genlux has acquired for it comprises a goniophotometer and a spectrometer, which operate automatically in tandem when testing lighting products or simulations of lighting designs.

“The synergy between the two instruments enables them to optimise lighting designs, ensure uniform illumination, evaluate colour quality and enhance energy efficiency,” Ian explained.

“The goniophotometer may best be described as a sophisticated specialised computer and is situated at one end of the rectangular lab, while the spectrometer, which is situated at the other end of the lab facing the goniophotometer, is a specialised high-tech camera.

The luminaire that has to undergo testing is mounted on the top of the goniophotometer and in the test procedure the luminaire is rotated in a series of different angles to enable the two instruments to register and record the luminaire intensity and distribution.

”The pair of instruments produce photometry data files in accordance with an internationally-recognised data file format which are fed into lighting design software programs, which in turn generate the lighting design simulations that are tested for accuracy and effectiveness,” Ian concluded