Introduction

Co-generation plants are designed to deliver both electricity and useful heat, making them highly efficient systems. However, the performance of such plants can degrade over time due to equipment wear, changes in operational conditions, or inefficiencies in maintenance practices. In this context, regular visual inspections and operational audits are essential for identifying potential areas of improvement. Quantifying the recommendations that stem from these audits using numerical techniques can provide a roadmap for operators to prioritize maintenance efforts and implement cost-effective solutions.

This article focuses on the value of numerical modelling to translate the visual inspection and operational audit report findings into actionable improvements. This article highlights the results of a case study conducted at a sugar mill co-generation plant, operating in full condensing mode, where advanced numerical methods were used to evaluate the impact of specific recommendations on plant efficiency. The study highlights how quantifiable improvements in key performance metrics, such as the power-to-coal ratio, can aid operators in making informed decisions about maintenance priorities.

The Role of Visual Inspections and Operational Audits

Visual inspections and operational audits provide valuable insights into the condition of critical components in co-generation plants. For instance, during an audit, factors such as superheater fouling, air preheater performance, and excess air levels in the furnace can be assessed. However, the challenge for plant operators lies in quantifying the potential benefits of addressing these issues and determining which maintenance actions will yield the most significant improvements in plant efficiency.

This is where numerical modelling becomes indispensable. By integrating data from audits with advanced process simulation tools, it becomes possible to quantify the impact of different maintenance actions on the overall plant performance. Numerical techniques allow for a detailed analysis of how operational changes, such as reducing excess air or improving heat exchanger performance, affect thermal efficiency and power generation.

Case Study: Sugar Mill Co-generation Plant - (Full condensing mode, zero process steam)

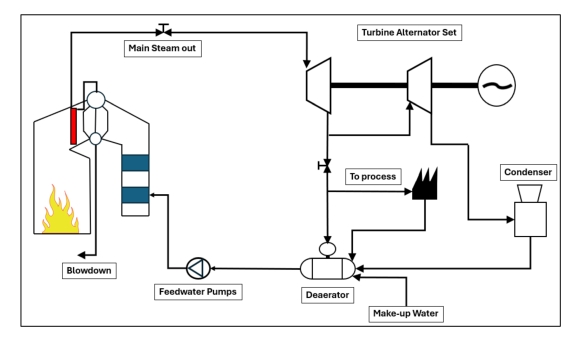

A recent study conducted at a co-generation plant provides a practical example of how numerical techniques can be used to quantify audit-based recommendations. The plant consists of two boilers, each with dedicated turbo-alternator set, that operate primarily on coal during the off-crop season and is bound by a power purchase agreement (PPA) with the national grid utility requiring the delivery of a specific efficiency target of 1.4 MWh per ton of coal burned. According to the PPA, in this instance, the coal is supplied to the sugar mill by the utility company.

The study leveraged numerical models to simulate the entire co-generation system, from the boilers to the turbines and condensers. Using actual plant data and the findings from a recent operational audit, the model was tuned to match current plant performance. Several key recommendations were tested in the model, revealing potential improvements in thermal efficiency and power output.

Quantified Recommendations and Results

Based on the operational audit, the following key areas were identified for improvement:

- Superheater fouling and reinstatement: The audit revealed that some superheater elements were blanked off or fouled, preventing the boiler from reaching its target steam temperature. Numerical modelling showed that reinstating these elements could raise the exit steam temperature to the desired 440°C, which would improve turbine efficiency and increase the power-to-coal ratio by approximately 2%.

- Air Preheater optimisation: The audit suggested that increasing the under-grate air temperature of the first boiler by using bleed steam from one of the turbines, could improve combustion efficiency. Numerical simulations confirmed that this modification could lead to a 1.5% improvement in the power-to-fuel ratio.

- Excess air control: Excess air was identified as a critical issue in both boilers. By reducing the final oxygen content in the flue gas through better excess air control, the numerical model indicated a further 2% increase in plant efficiency. Optimising the combustion air reduces the heat losses associated with unnecessary excess.

- Condenser performance: The study found that the plant’s condenser was underperforming, leading to a higher turbine exhaust pressure resulting in a reduced power output. Numerical analysis suggested that improving the condenser’s performance could boost the power-to-coal ratio by up to 15%, significantly improving the plant’s ability to meet the PPA requirements.

Prioritizing Maintenance Based on Quantifiable Data

The ability to quantify the benefits of various recommendations gives plant operators a clear understanding of where to focus their maintenance efforts. In the case study, the combination of reinstating superheater elements, optimizing air preheating, and controlling excess air levels provided a cumulative efficiency improvement of nearly 5%. When condenser improvements were factored in, the overall plant efficiency could increase by as much as 15%, allowing the plant to meet its contractual efficiency targets.

This quantifiable approach also enables power plant operators/owners to justify and prioritise capital expenditures for maintenance projects. Instead of relying on qualitative assessments, power plant operators/owners can now demonstrate to their stake holders, the potential return on investment by showing the projected gains in power output and fuel efficiency based on numerical simulations.

Conclusion

In co-generation plants, visual inspections and operational audits are invaluable for identifying areas where performance improvements can be made. However, the ability to quantify the impact of these recommendations using numerical techniques is key to helping operators prioritize maintenance actions and optimize plant performance.

The case study at the sugar mill co-generation plant demonstrates how numerical modelling can translate audit findings into tangible improvements. By implementing targeted recommendations, the plant operators can increase the power-to-coal ratio, ensuring compliance with efficiency targets and improving overall plant financial viability.

This approach underscores the importance of coupling traditional inspection methods with advanced numerical analysis to make data-driven decisions in optimizing co-generation and power plants, especially when coal is used as a primary fuel source.

By Dr Brad Rawlins align="left">Mechanical R&D Engineer John Thompson