MV Switchgear’s services unit, WPI Power Solutions, which procures, installs, repairs, refurbishes and maintains electrical networks in the local market, was contracted by a leading Mpumalanga-based petro-chemical company in September last year to procure and install new bus-ducting, busbars and post-insulators in one of the company’s plants, following the destruction of these items of equipment in a fire.

High Voltage Equipment (HVE) was awarded the contract to manufacture and supply the bus ducting and busbars, while requesting one of its technology partners in Europe to quote for the manufacture and supply of the replacement epoxy resin post-insulators used to support the main conductor of the bus-ducting

The customer however was unhappy with the lead time for delivery quoted by the oversees supplier and asked WPI to find an alternative solution for the required post-insulators to expedite the restoration of supply to their operations. WPI approached MV Switchgear to do so, as it manufactures similar post-insulators for some of its own switchgear equipment. These however were found to be unsuitable, as their dimensions did not match those of the required units.

MV Switchgear then turned to Motic in China, an international electrical equipment manufacturer and supplier with which it has close ties, as one of Motic’s subsidiaries has supplied specialised GELPAG-branded solid insulated switchgear (SIS) units to the division for installation in a number of major local projects in recent years.

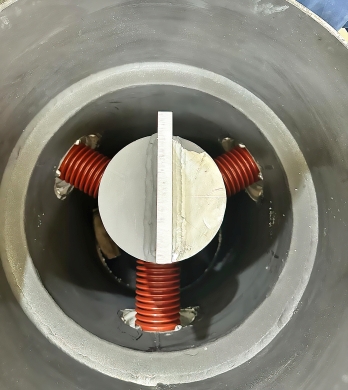

MV Switchgear selected from Motic’s catalogue the post-insulator model that most closely matched the originals and ordered 30 of these units, to which it still had to make substantial modifications to suit the application. These were:

- Trimming off a small portion of the top of each insulator to the correct length.

- Machining out a cavity at the top of each unit to accommodate a rubberised busbar support spacer that WPI arranged to have manufactured locally.

- Machining new aluminium busbar supports.

- Manufacturing by a local contractor arranged by WPI of purpose-designed flanges for mounting the new post-insulators to the bus-ducting.

“After completing assembly of the post-insulators we had them type tested for lightning impulse withstand at the SA Bureau of Standards’ National Electrical Test Facility (NETFA) in Pretoria, followed by power frequency withstand and partial discharge tests conducted in our own plant,” said Johan Jordaan, MV Switchgear’s Technology Development Specialist.

“We then did a trial assembly of the post-insulators on the newly-manufactured busbar ducts to verify the assembly interfaces of the post-insulators and bus-ducting before having them shipped to site for installation by the contractor appointed by WPI,” he added.

The insulators were ready to be shipped to site on December 5 last year, with installation on site being performed by WPI’s Secunda branch and completed on December 22.

“We succeeded in cutting the lead time for manufacture, modification and delivery of the replacement post-insulators by about two months, compared with the lead time first quoted from Europe. Due to our quicker delivery the customer was able to return the plant to service much sooner, thereby achieving substantial savings,” Johan concluded.