Switched Reluctance (SR) technology

Reid & Mitchell (R&M) has joined forces with Komatsu SA on a new project as its local service provider on key electrical machine components.

This new venture commenced when Komatsu SA approached R&M recently to repair and test Switched Reluctance generators & motors used on SR hybrid front-end loaders in the mining industry.

Switched Reluctance technology has been developed as a viable alternative to DC and AC technology in electric traction drive applications, as it has been found not only to significantly improve machine efficiency, reliability and durability, but also achieves substantial cost savings by comparison with the conventional technologies in this field.

How does this “revolutionary” new technology work and what are the significant benefits it has been shown to have over the standard technologies applied for similar purposes?

Although SRM is dubbed today as “new”, it was in fact invented way back in 1838 and was initially designed to propel locomotives which used mechanical switches to control the motor speed.

After development had been undertaken by a team of engineers in Europe in the early-1990’s, Komatsu, in recognising the potential of the technology for use in some of its own equipment, made further advances in its development in the early-2000’s and shortly thereafter transitioned its entire wheel-loader product line to SR technology.

An SR motor can put out the equivalent power of a larger one in a smaller package. The rotating portion of an SR motor is lighter, which translates to less stress on the gear train, improving life cycle and duty cycle on components. Additionally, SR has a significantly higher speed capability compared to other motors.

Komatsu sought to best meet customers’ needs for improved efficiency, reduced fuel usage, lower cost per tonne and equipment that is rugged and durable enough to stand up to harsh conditions and constant use, plus extra reliability and reduced maintenance costs.

The company has also increased energy storage by creating the Kinetic Energy Storage System (KESS) deep energy storage system to work with its current SR technology, reducing a machine’s overall fuel consumption by up to 45%. The KESS unit provides a means of deep storage of regenerated energy, which can be used to supplement engine power to enhance machine acceleration and dramatically improve loading cycle times, with reduced diesel emissions.

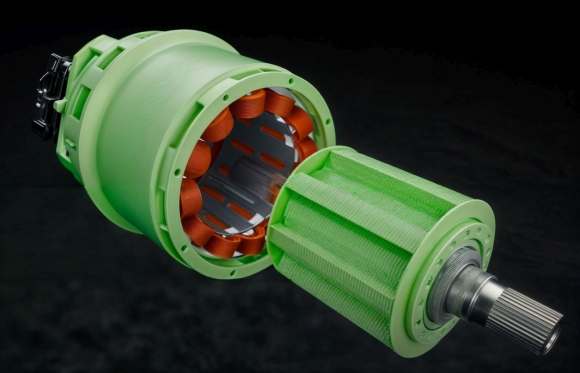

The Switched Reluctance Motor (SRM) is an electric motor that runs by reluctance torque and thus is a subgroup in reluctance motors. Unlike common brushed DC motor types, power is delivered to windings in the stator rather than the rotor. This greatly simplifies mechanical design as power does not have to be delivered to a moving part, which eliminates the need for a commutator, but it complicates the electrical design as some sort of switching system needs to be used to deliver power ro the different windings. Electronic devices can precisely time the switching of currents, facilitating SRM configurations. Its main drawback is torque ripple. Controller technology that limits torque ripple at low speeds has been demonstrated.

Furthermore the switched reluctance motor has been extended to become a switched reluctance generator (SRG), since topology that is both motor and generator is useful for starting the prime mover, as it saves a dedicated starter motor.

SRM operating principle

Even though the construction is simple, the control is not an easy task for the SRM, since the phase energizing should be implemented at the right angle, to have less speed oscillations.

Another issue is the double saliency construction on both the rotor and stator, so that torque production by separate phases result in large torque ripples. This effect also produces current ripple in the DC supply and to a demand of a large filter capacitor. In addition, another negative effect of the torque ripple is the acoustic noise, due to the induced radial magnetic forces.

Great advances have been made recently with power electronics and microprocessors to overcome some of the other complications arising from SRM. More accurate control allows precise control.

To sum up, SRM’s are cheap, robust, no winding in the rotor, have a very simple construction and are fault tolerant. The SRM has wound field coils, as in a DC motor, for the stator windings. The rotor is a solid salient-pole rotor made of soft magnetic material. When power is applied to the stator windings, the rotor’s magnetic reluctance creates a force that attempts to align the rotor pole with the nearest stator pole.

To maintain rotation, an electronic control system switches on the windings of successive stator poles in sequence so that the magnetic field of the stator “leads” the rotor pole, pulling it forward. The switched-reluctance motor uses an electronic position sensor to determine the angle of the rotor shaft and solid state electronics to switch the stator windings, which enables dynamic control of pulse timing and shaping.

In an SRM the rotor magnetisation is static, while an induction motor has slip. SRM’s absence of slip makes it possible to know the rotor position exactly, allowing the motor to be stepped arbitrarily slowly.

How SRM technology works in SR hybrid vehicles

The process to capture the regenerated energy begins when diesel energy is converted to electrical energy through a SR generator, which provides power to the motors to make the wheels rotate.

When the operator eases off the accelerator, the demand for diesel stops but machine momentum keeps the motors rotating. At this point, the motors become generators, supplying energy to a Kinetic Energy Storage System (KESS). When the operator presses the pedal again, the KESS supplies the stored energy while the engine simultaneously supplies diesel energy. The result is the equivalent of doubling the engine horsepower.

To make this possible, Komatsu’s engineers investigated ultra-capacitor energy storage along with battery storage. Compared to other motor technologies, the SR hybrid drive’s high-speed capability made SR kinetic energy storage feasible and more favourable against other available energy storage devices.

SRM’s advantages

The advantages of SRM over AC and DC technology include :

- Less impact stress on gearing and high-torque-to-inertia ratio means faster response.

- Lower switching frequency as compared to AC systems, resulting in longer power electronics and motor insulation life.

- Simple rugged design made up of a stack of electrical steel laminations.

- No windings, rotor bars, magnets or contacts of any kind.

- Short end turns permit very high torque/volume ratio for an electric drive

- Independently wound coils have no overlap areas.

- Good thermal management, since losses are easily dissipated through the outer circumference.

By Willie Liebenberg

Technical Executive

Reid & Mitchell