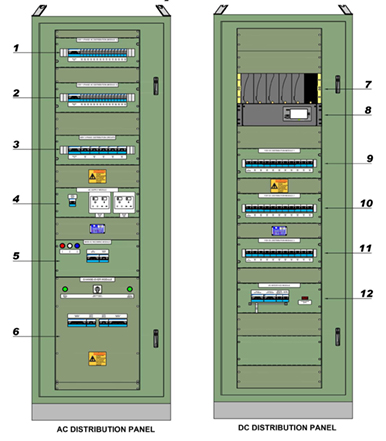

Static Power has introduced modular auxiliary AC and DC distribution panels for electrical substations into the market.

The highly versatile modular panels have been developed by ACTOM’s Static Power business in response to market demand to replace the traditional customised AC/DC panels, which are not easily modified.

The modular 19” racks have back plate connections that can easily be installed into 19” swing frame AC/DC distribution panels.

This new product, developed since early-2020, was introduced in mid-2021.

“In just short of a year, the modular AC and DC DB concept has gained widespread acceptance by major customers for use in substations. Several orders have been received to date in both the local and export markets and orders are increasing monthly as the market becomes more exposed to the concept,” said Tony Gordon, Static Power’s Manager, Technical Sales, and leader of the development team.

The AC and DC racks developed, have different functions.

The exciting new approach that Static has embarked on features, among many others, the following:

- In the AC rack portfolio, there are 3-phase dual AC chop-over racks, yard lighting racks with photocell sensor, and 3-phase and single phase AC distribution racks.

- In the DC rack portfolio there are emergency lighting racks, 50V dc 110V dc/220V dc distribution racks, DC/DC converter racks of all ranges (e.g. 110V dc to 48V dc), DC to AC inverter racks, and modular 24V dc, 48V dc, 110V dc and 220V dc switch-mode battery charger racks of varying power ratings.

- AC modular inverter racks which is from 48/110/220V DC to 230V AC

- DC power racks systems (modular switch-mode battery chargers), which can be easily integrated into existing substation AC/DC swing-frame cabinets.

- Interface racks to allow easy connection to modular UPS and switch-mode battery charger racks are also available.

“The modular rack system approach has enormous advantages over the traditional customised product,” Tony pointed out.

“Not only is the cost of production much lower as the racks are standard, but speed of manufacture and assembly is faster than the traditional AC or DC distribution panel concept. The greatest advantage of the modular rack design is that the expansion of a modular 19” distribution board is very simple, by removing blanking plates and inserting a rack.”

“This allows customers to expand existing distribution panels at site when there are changing needs. This is in sharp contrast to the inflexibility that characterised the traditional distribution board system, where panels were fixed and unchangeable and therefore had to be replaced entirely by a new one whenever a customer’s requirements changed, so adding to the cost.”

All the modular panels are of standard 19” design and are designed to fit onto a swing-door cabinet. This allows easy access to the terminations of each rack’s back plates, which are mounted inside the cabinets.

“The distribution panels are either 32U or 47U in height.

A typical DC panel, can have a 48/110/220V DC switch-mode battery charger system, including AC-DC interface module, emergency light module, several DC distribution modules, as well as 48/110/220V DC input to 230V AC sine wave inverter included.

A typical AC panel can have a dual 3-phase AC input rack, 3-phase and single-phase AC output racks, 3-phase external AC plugs as well as single-phase AC plug tops that can be used by personnel inside the substation.

In some cases the AC input and distribution can be accommodated with the DC requirements, thus saving space in smaller substations.

“There are up to 10 off AC modules designs and 15 off DC racks available. This should provide the customer with an array of potential functions required at a substation,” Tony concluded.