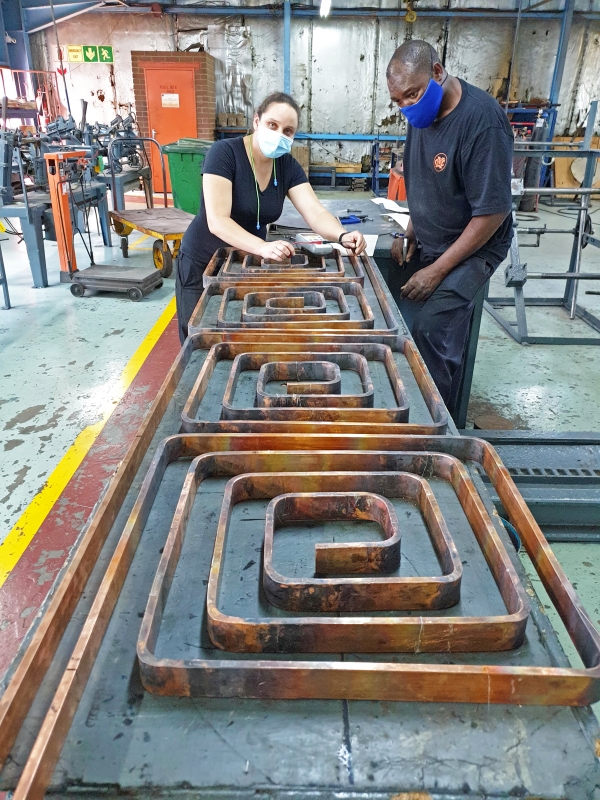

M&C’s Maria Drodskie, Test Department Foreman, and John Mtimkulu, Coil Former, perform the final inductance measurements of the four inductors for the School of Electrical & Information Engineering’s new LISN.

ACTOM has continued its ongoing support of Wits University’s School of Electrical & Information Engineering by manufacturing and supplying complimentary equipment it requires to enable it to provide more advanced services to industry, while further enhancing learning opportunities for its students.

Projects at the School to which the group has contributed funding, equipment and skills on previous occasions were:l Funding and supplying a range of equipment for a major upgrade of the School’s energy laboratory in 2011 and 2012. The modernised lab, named the ACTOM Energy Lab, was officially opened in early-2013.

l Donation by Electrical Machines of two 5.5kW 400V 4-pole foot-mounted cast iron motors in August 2013.

l Servicing and repairing the aging motor-alternator sets in the School’s ACTOM Energy Lab by Marthinusen & Coutts on ACTOM’S behalf in 2015.

l Donating 24 high accuracy 15 VA current transformers from Current Electric for incorporation in a stand-alone electrical micro-grid the School established in the ACTOM Energy Lab in 2017.

The latest project in which ACTOM has been involved is a substantial upgrade of a line impedance stabilisation network (LISN) the School requires for testing of high power AC and DC equipment, particularly when measuring and evaluating the emissions from a piece of equipment. The school already has a range of impulse generators that can create lightning-like surges to perform immunity tests on equipment fitted with lightning arrestors, etc.A LISN performs an important filtering function when testing electrical equipment for electromagnetic compatibility (EMC) between it and its power source, as equipment that is not designed and tested for EMC can create conducted interference, which can compromise sensitive electronic equipment around it.

There is also legislation and standards that regulate EMC and the testing required for it.The School’s first LISN was designed with the ultimate aim of using it in service to industry to test industrial equipment for EMC related to its emissions. However, the original equipment commissioned around 2009 was rated for a continuous current of 15A, which is only suitable for testing of domestic appliances and DIY equipment like electric drills and grinders.

The new LISN allows testing of three-phase equipment up to 600A and 400V and is well suited for testing of a wide range of industrial electrical machines. “The design is modular and will allow single and three-phase testing. The maximum power rating facilitates not just testing in the laboratory but also in-situ testing in the field,” said Prof Willie Cronje, the School’s Head of the Alstom Chair for Clean Energy Systems Technology, who is leading the LISN project.

The School developed some of the equipment for the new LISN in-house, while approaching ACTOM for the high-current inductors and EMC specialist companies to provide the balance of equipment, such as the capacitors and shielded enclosures. Marthinusen & Coutts (M&C) has suitable infrastructure and experience in making high-current coils, so they agreed to design and manufacture the inductors for the LISN.

“We don’t normally manufacture inductors, but we are accustomed to undertaking research to design and manufacture specific items as part of our services, so producing these inductors posed no problems for us,” said Rob Melaia, M&C’s Engineering & Technical Executive.The new LISN can be configured up to a four-wire three-phase system requiring four inductors, which M&C designed and produced during September, October and November this year.

“The inductors are air-cooled, as well as air-cored, and hence linear, which is the correct design for achieving and maintaining constant inductance. The inductors are manufactured with thick cross-section copper bus bar (10mm x 40mm) in a square coil configuration with substantial clearance between adjacent turns to minimise parasitic capacitance,” Rob explained. Prof Cronje commented: “This LISN with the right spectrum analyser and other equipment will facilitate trouble-shooting and fix problems that contribute to interference in nearby systems.”