Occasionally, customers approach ACTOM MV Switchgear for unique solutions required for specific applications. One such case was a request for a three-panel primary switchboard housed in an outdoor enclosure.

“The three-panel solution was needed for a changeover facility between the primary (11kV) supply and the incoming supply from a PV solar and battery energy storage system installed for the Irene Village Mall”, said Rhett Kelly, MV Switchgear’s Design & Development Manager.

Due to the 25kA system fault level, the high number of circuit-breaker operations, sophisticated protection relays and generator controllers required for this application, secondary MV switchgear was unsuitable. The compact size and fixed-pattern format of the solid dielectric insulated GELPAG switchgear made it the ideal choice for this application.

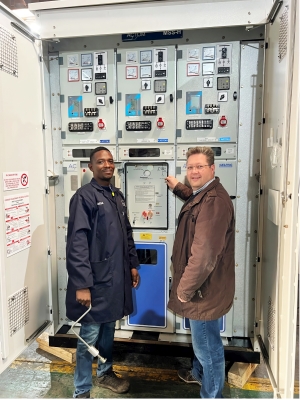

In near record time, MV Switchgear designed and manufactured an outdoor enclosure for three 1250A, 31.5kA GELPAG panels, each having a cable-side voltage transformer (VT) for voltage synchronisation. The design drew on the experience ACTOM has gained over the years in designing and testing outdoor enclosures for various types and sizes of MV switchgear. The switchboard was fully assembled and factory tested following IEC 62271-202 – the standard for prefabricated substations – which now includes prefabricated switchgear substations. The outdoor enclosure was despatched to the customer at the end of July.