ACTOM MV Switchgear successfully tested internal arc safety on their outdoor enclosure designed for the 36kV RMV ring main unit (RMU). The testing was done in June 2024 on the most common 3-way “LCL” non-extensible configuration, incorporating two ring switch-disconnectors and a circuit-breaker tee-off. The testing was conducted following IEC 62271-202, the international standard for prefabricated substations, to achieve an internal arc classification of IAC-AB 20 kA 0,5 s as prescribed in SANS 1874, the South African front-end standard for ring main units.

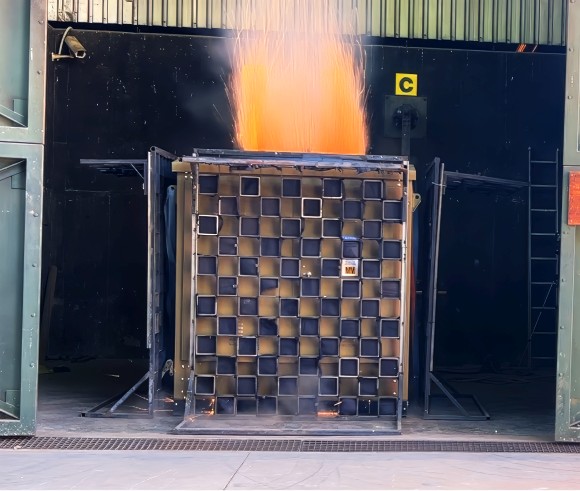

This required two tests to verify the enclosure’s arc venting capability. The first test was conducted for accessibility “A” with the enclosure doors open to verify operator safety if an internal arc fault occurs when standing in front of the unit. The second test was conducted for accessibility “B” with the enclosure doors closed and cotton indicators placed on all sides of the enclosure to verify the public’s safety in the vicinity of the enclosure.

“The discontinuation of the Schneider FLUSARC 36 kV rated RMU presented the ideal opportunity for us to conduct the testing on the 36kV rated version of the popular 12/24kV RMV product range previously internal arc tested”, said Rhett Kelly, MV Switchgear’s Design & Development Manager, and added “36kV rated switchgear is predominantly used for renewable energy wind farm applications in South Africa. Shortly after completing the testing, we received the first 36kV outdoor unit order from a prominent mining company.”

The results from the test conducted on the 3-way “LCL” outdoor enclosure can be transferred to other RMU configurations using the rules and guidance provided in IEC 62271-312 without further testing.

While at SABS NETFA, ACTOM MV Switchgear also tested internal arc on its pedestal and arc duct solution developed for the indoor extensible RMV units. The tests were carried out following IEC 62271-200, successfully achieving an internal arc classification of IAC AFLR 20 kA 1 s.

As indoor units are only accessible to authorised personnel, only one test for accessibility “A” was required – with cotton indicators positioned at the front, lateral and rear sides of the switchgear with a mock-up room simulation.

“As the vertical arc duct incorporates an internal arc pressure relief device with arc ‘coolers’, we opted to test with a ceiling height of only 3m above the floor level. Furthermore, although SANS 1874 only requires a fault duration of 0,5s, we were fairly confident that we could achieve a full 1s test duration based on the design and experience gained from years of extensive internal arc testing,” concluded Kelly.